How Does a Brazed Plate Heat Exchanger Work?

2025-07-05 | Heat Exchanger

Brazed plate heat exchangers (BPHEs) have become a staple in modern thermal systems thanks to their thermal efficiency, compact design, and ability to operate under high pressure conditions. Whether used in refrigeration, district energy, or industrial processes, these units provide reliable and efficient heat transfer. In this article, we’ll explore how a brazed plate heat exchanger works, what makes it effective, and how it compares to other designs like gasketed plate heat exchangers.

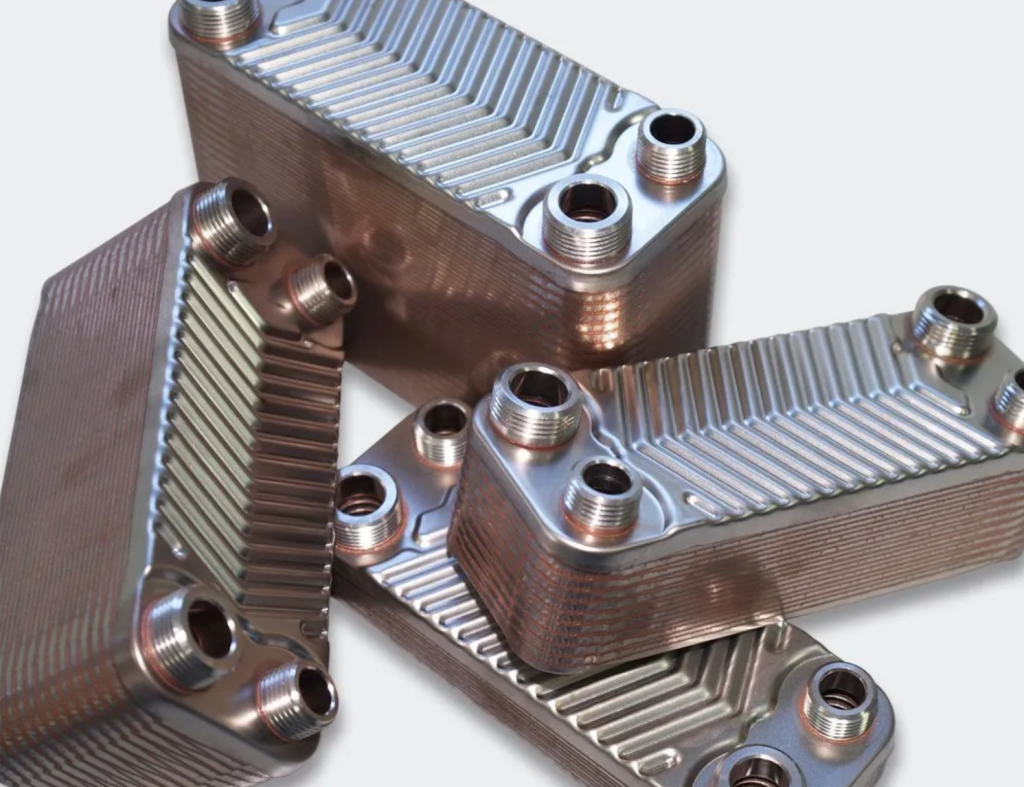

A brazed plate heat exchanger is a type of heat exchanger that uses a series of corrugated plates, usually made from stainless steel, to transfer heat between two fluids without mixing them. The plates are stacked together and vacuum brazed using a filler material—typically copper or nickel—which permanently seals the plates and forms a solid, leak-proof assembly.

The working principle of a BPHE is based on the flow of hot and cold fluids through alternating channels between the plates. Here's how it works:

This design enables efficient energy exchange even in compact spaces.

BPHEs are versatile and used across a wide range of applications:

Both brazed and gasketed plate heat exchangers serve the same purpose but differ significantly in design and application:

| Feature | Brazed Plate | Gasketed Plate |

|---|---|---|

| Seal Type | Vacuum brazed | Rubber gaskets |

| Maintenance | Low | Easy to maintain |

| Pressure Rating | High | Moderate |

| Size | Compact | Larger |

| Suitable For | Closed systems | Systems needing frequent cleaning |

| Cost | Lower initial cost | Higher, but more flexible |

For systems where cleanliness, flexibility, and easy disassembly are key, gasketed designs are preferable. However, for compact, high-pressure systems requiring minimal maintenance, brazed designs are often the better choice.

Understanding how a brazed plate heat exchanger works reveals why it's favored in so many thermal applications. With its compact design, high thermal efficiency, durable vacuum brazed construction, and efficient plate design, it offers a superior solution for both residential and industrial systems. Whether you’re designing a new refrigeration unit or upgrading a district energy system, a BPHE provides reliable performance across a wide range of scenarios.