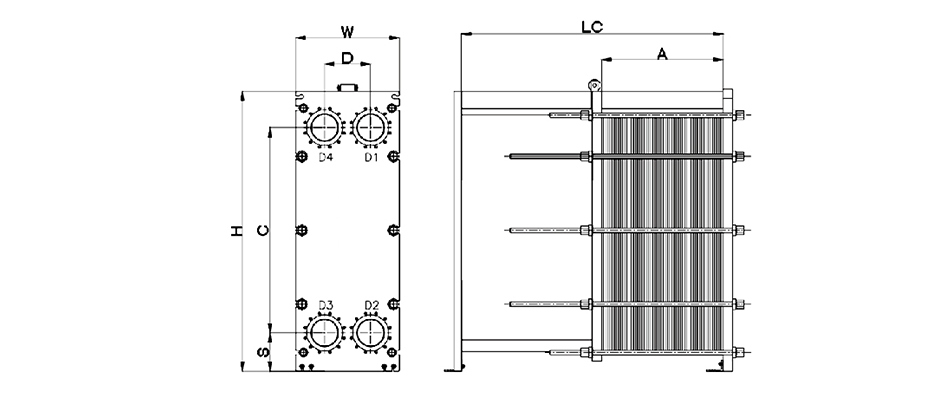

A gasketed plate heat exchanger is a versatile and efficient type of heat exchanger widely used in chemical processing and various industrial applications. It consists of modular plate heat exchanger units, where heat transfer plates are arranged with gaskets to create sealed channels for fluids. This design allows for effective counter current flow, enhancing heat transfer efficiency between hot and cold streams. Compared to traditional shell and tube heat exchangers, gasketed plate and frame heat exchangers offer easier maintenance, flexibility, and lower operating costs. Variants such as semi welded plate heat exchangers combine the benefits of both gasketed and welded designs, making them suitable for demanding environments. The modular nature of these exchangers enables customization and scalability, making them ideal for a broad range of industrial processes requiring efficient thermal management.

Plate Heat Exchanger (abbreviated as PHE), is a type of heat exchanger used to transfer heat between two fluids. It typically consists of a series of parallel-arranged metal plates with gaps between them, allowing two fluids to exchange heat without direct mixing. This design enables efficient heat transfer while maintaining fluid separation.

Essentially, the working principle of a plate heat exchanger involves one fluid flowing on one side of the metal plates while the other fluid flows on the other side of the plates, allowing heat to be transferred between them. The corrugated design of the metal plates increases the surface area, thereby enhancing heat exchange efficiency.

Efficient Heat Transfer: Due to the small gaps between plates and the corrugated structure, heat exchange efficiency is very high, enabling fluids to transfer heat rapidly.

Smaller Footprint: Compared to traditional shell-and-tube heat exchangers, plate heat exchangers occupy less space, which is particularly useful in limited areas.

Easy Cleaning and Maintenance: The structure of plate heat exchangers makes them relatively easy to disassemble and clean, maintaining high operational efficiency.

Flexibility: The modular design of plate heat exchangers allows for expansion or reduction according to needs, adapting to different applications.

Plate heat exchangers are widely used in various industries including heating, cooling, food processing, chemical engineering, energy production, etc., for transferring energy or regulating fluid temperatures.